The key to the success of the European automotive industry is connected not only with the experience and developments of the largest automotive concerns. Make a significant contribution European parts manufacturers.

French, Dutch and german spare parts for cars popular not only among numerous private consumers. Most of the suppliers supply the conveyors of the largest automobile plants. Moreover, this category of enterprises not only offers the assembly of parts to order, but also conducts its own scientific and technical developments, which subsequently are in high demand.

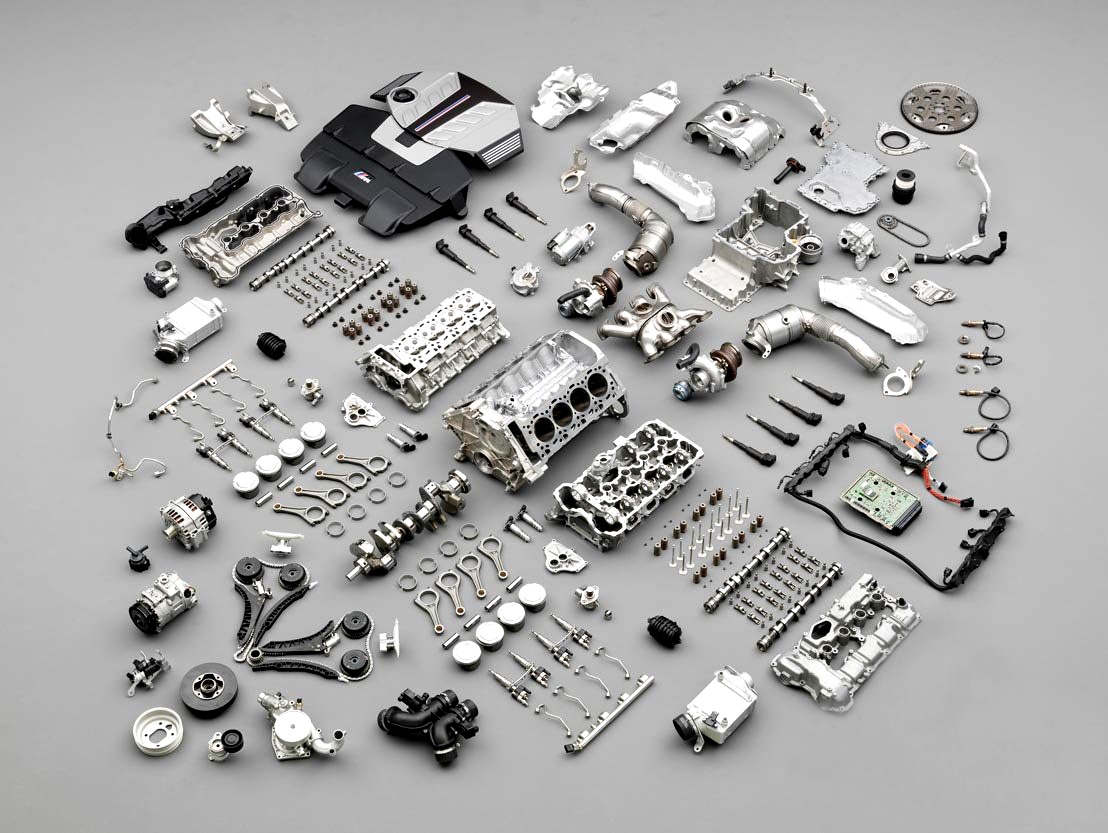

European automotive parts industry: the world's largest manufacturing hub

The largest factories in Europe engaged in the production of spare parts are full-fledged participants in the European automotive market and largely form the strategy for the development of the regional industry as part of their activities. A significant part of the enterprises is completely independent from the automotive concerns of Europe, and the sale of products is carried out all over the world.

Among the European manufacturers of spare parts there are a number of brands with a worldwide reputation. Among them are the German industrial concerns Bosch, SWAG, INA, Lemforder and Sachs. Each of these companies has made a knowledge-intensive contribution to the production of spare parts, participates in leading industrial initiatives for the development of the automotive industry in Europe.

A striking example of active work with foreign buyers is the Dutch manufacturer NIPPARTS BV, which provides sorting and packaging production services for a number of manufacturers in the Asia-Pacific region. The brand also produces brake pads and other car parts in accordance with EU regulation No. 1400/2002 and TUV and ECE R90 standards.

NIPPARTS products are tested in the leading testing laboratories of the EU, more than 16 thousand items of spare parts are produced for 4 thousand cars manufactured in the Asia-Pacific region. The company is engaged in the supply of parts to Japan. Spare parts from Europe, supplied by this company, are well known to the owners of Japanese cars and are perceived by many as Japanese.

The largest manufacturers of spare parts for automobiles form the scientific, technological and production base of the European region, which is not inferior in importance to the assets of automotive concerns. The leading position in this area is occupied by German companies. However, they are not a panacea, the auto parts industry continues to grow throughout Europe.

Eastern European enterprises are very active on the market, in particular, Czech factories engaged in the production of spare parts. A current example is the StarLine brand, engaged in the production of shock absorbers, supports, suspension springs, anthers and shock absorber bumpers. The products have proven themselves well for the combination of safety and vehicle stability.

European auto parts manufacturers: Germany leads the way

German spare parts manufacturers occupy a leading position in the market, and the market strategy is formed not only by large concerns, but also by small enterprises specializing in unique developments. This review will be useful to those readers who are interested in affordable technological solutions, as well as the optimal ratio of price and quality of car spare parts produced on the European market.

INA, FAG, LUK, Ruville are brands of the Schaeffler Group

The German concern Schaeffler Group began its history in 1883 with the development by Friedrich Fischer of a machine for the manufacture of round steel balls, subsequently used in bearings. The company itself, called INA, dates back to 1943, when it was registered in 1946 by the brothers Wilhelm and Georg Scheffler. Subsequently, the FAG concern, which began its history in 1905, entered the Schaeffler Group.

Currently, the company is Europe's largest manufacturer of rolling bearings and related spare parts and products for the automotive and aerospace industries. Wilhelm and Georg Scheffler defended their doctoral dissertations on this topic and were involved in the implementation of developments in the post-war period. The production is based on the production of a needle bearing developed by Georg Scheffler. Subsequently, it was proven in practice that the proposed bearing design provided highly reliable industrial solutions in the field of automotive and aircraft assembly.

The Schaeffler Group was formed in 2003 by the merger of INA, FAG and LuK, and the group is also a major shareholder of Continental AG. In 2009, Schaeffler Group CEO Jürgen Geisanger took over the World Bearing Association. Today, the Schaeffler Group has 39 factories in different countries of the world, so the marking on the place of production may be different. Manufacturing plants for the production of spare parts are also located in the USA, Canada, China, Thailand and Russia.

Schaeffler Group range

The Schaeffler Group currently manufactures spare parts for vehicles in three categories:

- cars;

- light commercial vehicles;

- heavy commercial vehicles.

The company specializes in the production of suspension parts, in particular, wheel bearings. Such solutions make it possible to fundamentally raise the level of equipment, use integrated sensors and other electromagnetic elements that ensure safety and driving comfort in dynamics. The range includes angular velocity joints (CV joints), repair kits for axles and suspension, steering, stabilizers and precision dust boots. Produced supports for gearboxes and engines.

Technical solutions from LuK

The manufacturer offers repair solutions for engines - drives for timing and auxiliary units, valve mechanisms and cooling. Innovative LuK brand transmission parts are offered:

- LuK clutches provide smooth acceleration and instantaneous gear changes even for heavily loaded vehicles;

- LuK dual-mass flywheel for the transmission significantly reduces vibration and noise, also ensures smooth shifting of the gearbox and contributes to lower fuel consumption;

- Clutch disengagement is based on hydraulic release systems replacing the cable clutch. As a result, the wear of parts is conceptually reduced and driving comfort is increased;

- reliable kits for high-quality transmission repair are produced.

It is worth noting that the products of the Schaeffler Group factories differ significantly. Lose as European production sites, especially the Slovenian division. This significantly increases the demand for Canadian components sold under the INA brand.

Roller bearings of the German brand FAG are distinguished by a stable level of production. Products can be found under the brand name Ruville. This is a packer of German spare parts INA, FAG for cars. Under this brand, suspension parts, CV joints, spare parts for the chassis, cooling pumps of a fairly high quality are often sold.

Robert Bosch GmbH

The history of the German concern Bosch begins with a small "Workshop of fine mechanics and electrical engineering" in 1886. Initially, only two people worked in it. Robert Bosch opened a workshop with money from his father's inheritance. In 1887, the first ignition system for internal combustion engines was developed. Bosch's solution became a replacement for dangerous Daimler pipes.

For the production of spare parts for ignition in 1909, a factory was opened in the German city of Feuerbach, in subsequent years the company began to produce starters, horns, direction indicators and windshield wipers. Already in the 1920s, the range of automotive components was significantly expanded, and in 1927, a fuel injection pump for diesel truck engines began to be produced, then for passenger cars.

The period 1933-1945 was characterized by serious controversy for Bosch. Some employees actively supported the Third Reich, while others categorically rejected it, which created certain development risks before and after World War II. To avoid negative consequences in 1937, Robert Bosch changed the form of ownership of the enterprise, transferred it from a joint-stock company to a limited liability company in order to keep the business for family members. By the end of 1945, almost all production facilities were destroyed, but the founder did not see this, having died in 1942.

Bosch Technical Achievements in the Parts Industry

In the period from 1946 to 1959, an active phase of development and production of spare parts for cars began:

- fuel pumps with electronic injection (1967);

- anti-lock braking system ABS, first installed on Mercedes-Benz (1978);

- an electronic control unit for a diesel engine (1986);

- navigation systems Blaupunkt TravelPilot (1989).

In subsequent years, the scientific and technical base of the enterprise was significantly expanded. Bosch now supplies parts for 70% conveyors to car manufacturers around the world. The company has an advanced production base that sets the vector for the development of the entire automotive industry. Develops a number of areas of activity at once. Collectively, Bosch files at least 5,000 patents worldwide each year. During the reporting financial period, about 70 billion euros are invested in development.

The first modern successes are associated with the development of electronic stabilization ESP, gasoline direct injection system, high pressure fuel pump, adaptive cruise control, drives for the first electric vehicles that left the assembly line in 2010.

At the moment, this largest German company produces almost all groups of auto parts for cars: windshield wipers, batteries, car lamps and filters, spark plugs, brakes, drive belts. The company develops and offers electronic components and accessories, including electric motors for interiors, lighting, interior comfort control systems. The range includes petrol and diesel engines, start/stop systems for micro-hybrid vehicles, steering, starters and alternators, and dynamic safety systems.

Lemförder, Boge, Sachs, Steyr are brands of ZF Friedrichshafen AG

ZF is one of the largest German suppliers of spare parts, founded by the outstanding German inventor and military figure Ferdinand von Zeppelin in 1915 (corresponding to the date of registration in the German Chamber of Commerce). Currently, the company is one of the 15 largest global suppliers of spare parts.

It is a supplier of products for Mercedes-Benz, Jeep, Maserati, Land Rover, Jaguar, BMW, DAF, Porsche and other automotive manufacturers. The technical base is focused primarily on cargo transport, the aviation industry, and agricultural machinery. The company acquired the assets of enterprises that are distinguished by high technical perfection in the design of manufactured shock absorbers.

Each brand that is part of ZF is a separate enterprise with its own scientific and technical base. All German companies are well known to consumers.

Lemforder

The German company Lemförder has more than 600 patents for spare parts for steering, silent blocks and chassis elements. The largest buyer is VW-Audi Group, almost all parts for conveyor assembly are produced by this manufacturer as part of ZF. The brand's products are also purchased by almost all major automakers. Among them are BMW, Volkswagen, GM, Mercedes-benz, Renault, PSA, FIAT, DAF, MAN, Honda, Ford, Nissan, Iveco, Porsche, Scania, Toyota and others.

Lemförder suspension and steering parts are considered the best and most advanced. The product range is represented by models of supports, racks, traction units, shafts, brake drums, CV joints, steering columns, drive belts, guide rollers, brake discs, as well as parts for author's cars.

Manufactured products comply with EU regulation No. 461/2010. According to many car owners, Lemförder auto parts are superior to branded originals. Spare parts are divided into two categories: those intended for installation in the service and suitable for self-repair. This purpose is marked on the box with a special symbol. The durability of Lemförder parts far exceeds the life of most branded parts of automotive corporations. These parts are used by Volvo.

BOGE

BOGE is a fairly well-known manufacturer of shock absorbers, anthers and bumpers, silent blocks and engine mounts. It is part of the ZF group. BOGE shock absorbers are exceptionally durable with 3-4 cycles of normal versions. This structural quality is achieved through the applied manufacturing process - induction hardening, surface chromium plating and micro polishing. In the manufacture, high-temperature oil treatment is used to obtain a high-strength surface layer, as well as special seals.

These German shock absorbers can be advised to people who are forced to drive off-road. BOGE will be able to solve your problems. The range is represented by three lines of shock absorbers: AutoMatic - standard, Turbo - for sports driving, Extreme - a particularly stable series of authorizers, the quality of which does not depend on driving conditions. The Boge Nivomat series allows you to adjust the height of the ride height depending on the type of riding and the season. Products are protected by a hologram (packaging and product).

SACHS

SACHS is the largest German manufacturer of special shock absorbers. Clutches and accompanying accessories are also offered. The main feature of the brand is the use of high quality materials. As a result, the products are distinguished not only by technical innovations in the field of mechanical systems, but also by durability and reliability.

SACHS' unique offerings include:

- repair kits;

- dual-mass flywheels that reduce vibration;

- clutch with XTEND system (wear compensation);

- clutch drive systems;

- shock absorbers with an increased level of safety and driving comfort, provide perfect traction and controllability of the car;

A distinctive feature of SACHS is the release of different types of shock absorbers to make it easier for manufacturers and end customers to choose products according to their requirements. Single and double tube struts, shock absorbers with spring plate, hydraulic ride height adjustment are offered. The company is experimenting not only with the design, but also with the materials from which the products are made.

SACHS produces lightweight aluminum dampers with variable tube wall thickness. Higher strength is provided precisely in those places that lend themselves to high mechanical loads. In other places, the ultimate subtlety is preserved. This product is designed for special purposes related to racing or hybrid car equipment, suspension struts are offered as a kit. The complex manufacturing process includes 17 production steps.

All SACHS products are subjected to numerous tests, including, in real critical conditions, in professional races. A significant part of the proposed equipment can be successfully operated on sports cars. This German company provides technical support available to all for the use of spare parts. When choosing SACHS, consumers choose to drive safely.

Steyr-1864-2001

Until 2001, ZF included the Austrian Steyr, founded in 1864. The company had a notable history in the automotive market, since in 1929 Ferdinand Porsche came to the position of chief engineer, who disagreed with Daimler-Benz. Led by him, the Austria 21/100PS large luxury car was designed, which had the first ever engine with removable heads, independent rear wheel suspension, was equipped with Lockheed all-wheel drive hydraulic brakes.

This model was not released to the series, as the creditor Steyr requested technical support from Austro-Daimler. Offended, Porsche left the company and founded his own bureau. Subsequently, he designed the first Volks-wagen for the Third Reich, Porsche has been constantly collaborating with Volkswagen to this day.

FEBI, SWAG – Bilstein Group brands

FEBI is a trademark of the German company Bilstein Group, derived from the short name of the company named after the founder FERDINAND BILSTEIN JR. The company began its history in 1818, at the beginning of history it was engaged in the sale of spring pins. At the moment, it is the largest manufacturer of spare parts, supplying its products to 140 countries of the world. Products are parts of engines, suspension, steering, brake systems. Filters and drive parts are supplied. Products are used on Mercedes-Benz, DAF assembly lines.

FEBI provides customers with a wide range of spare parts, including electrical equipment, transmission parts, ignition and cooling filters, fasteners. Products are of average quality, but at the same time a good combination of "price and quality".

In 2000, SWAG Autoteile Gmbh was acquired. In 2011, the British manufacturer ADL acquired the Blue Print brand, which in 2012 became part of the Bilstein Group. Now the group has three brands highly valued in the market FEBI, Blue Print, SWAG, and one of them is British. Blue Print has the highest quality thanks to the constant attention to product quality, this brand focuses on parts for Asian and American cars, primarily Japanese, Korean, Chinese and US models.

Behr-Hella, Hella, Mahle Gmbh are trademarks of the Behr Group

The Behr Group is an international company headquartered in New York, but brings together two of the largest German manufacturers of spare parts. Mahle Gmbh is considered the main and largest division. This supplier is considered one of the best manufacturers and packers of European spare parts with extensive control of the quality system, delivery and management.

The Behr-Hella brand specializes in the supply of high-tech, customer-optimized automotive climate control equipment. Hella manufactures the best automotive lighting on the market, including custom-made ones.

Hella KGaA Hueck & Co.

One of the world's leading German automotive lighting manufacturers. Included in the TOP-50 largest automotive suppliers in the world, founded in 1899 by Sally Windmüller under the name Westfälische Metall-Industrie Aktien-Gesellschaft (WMI). The main specialization at that time was kerosene lamps for trains.

The name HELLA was first used in 1908 as a trade name for acetylene headlights, and was adopted as the main company name in 1986. HELLA participates as a designer and builder of the largest distribution networks. At the moment, it has more than 100 places of presence, has a number of foreign production facilities.

To strengthen their positions, a decision was made on investment cooperation. The result was the joint brand Behr-Hella. Also, active production cooperation has been established with another German production, Mahle Behr. Joint ventures show high efficiency in the development of various solutions.

HELLA specializes in the development and production of standard spare parts and various customized solutions. Automotive lighting equipment is distinguished by the manufacturer's innovative proposals. For example, for the Cadillac Esacclade Platinum, adaptive headlights were developed that scan the space ahead of the vehicle and change the lighting depending on road conditions.

HELLA is well known to consumers as a manufacturer of xenon and bi-xenon headlights, halogen lamps for cars, and plastic windows. The products are subject to strict quality standards.

Behr-Hella Thermocontrol (BHTC)

Behr-Hella Thermocontrol (BHTC) combines the experience of HELLA and Behr to produce first-class air conditioning systems. Currently, in addition to the advanced Behr air conditioning systems, which have been known on the market for a long time, the company pays attention to climate control technologies and the creation of human-machine interfaces.

A joint venture between Hella, Behr and Plastic Omnium (a plastic solutions provider) produces high-tech bumpers, radiators and headlights. The main specialization is full-featured components for cars, climate control, interior and technical air conditioning, on-board wiring, as well as sensor solutions for cars and other areas.

Production covers the following product groups:

- heat exchangers for gear and engine oil;

- thermostats and radiators of cooling systems, coolers and heating equipment;

- viscous couplings and water pumps;

- fans and casings for them;

- temperature sensors for climate control;

- compressors;

- evaporators;

- filters;

- hoses and communication accessories for technical air conditioning and cabin climate control.

Innovative manufacturing activity is related to the release of adaptive climate systems for cars, but the scope of research technologies is much wider, aimed at obtaining the optimal human-machine interface architecture. For these purposes, a research center has been opened in Finland, with the aim of inheriting the experience of specialists and Nokia Microsoft Mobile. In 2018, more than 20 engineers will work in the center. The focus is on creative control concepts and intelligent user interfaces.

The company delivers to the largest automotive conveyors, in particular, it closely cooperates with OEMs. Every fourth car produced in the EU is equipped with Behr Group parts.

Mahle GmbH

Mahle Gmbh is the main division of the Behr Group. The company is engaged in the production of automotive parts and aftermarket service. In 2017, Mahle Gmbh was recognized as the best supplier of spare parts in Europe. Mahle Gmbh is a leader in hydraulic solutions for the automotive industry.

The innovative activity of the enterprise consists in cooperative work with the BHTC division in order to create an E-mobile transport with a human-machine interface. At the same time, the company plans to sell its stake in the BHTC joint venture and focus on the core business. The following types of products are produced for passenger cars.

Cooling systems

In this product category, the company offers a range of effective solutions:

- radiators and low-temperature radiators;

- coolant pumps;

- cooling modules;

- charging air cooling;

- oil heating and air conditioning;

- EGR coolers and batteries;

- electric heaters;

- saloon systems "frontend";

- thermostats and control valves.

The proposed parts and components are aimed at solving the problem of critical heating of engines. All components are designed for high loads. In the future, the company should provide coolers designed for any load in dynamics.

Piston systems

Pistons are offered that take into account the increase in loads in modern engines. Mahle Gmbh produces high-pressure pistons that help reduce fuel consumption. The product range includes petrol, forged and diesel pistons as well as piston assemblies.

Directional valves

The efforts of automotive systems developers are focused on optimizing the functionality of components. First of all, gas exchange in internal combustion engines can be optimized in order to optimize the emissions of combustion products into the environment. The valve plays a key role in this direction. The valve system is subjected to high loads and requires a special design approach. Mahle Gmbh pays special attention to materials and heat transfer of combustion products. This product category offers cam valves, chambers and brackets, guides and seat inserts made from high-tech raw materials.

Fuel components

Particular attention has been paid to fuel filtration to ensure effective protection of the engine from damage. As manufacturers increasingly adopt a modular approach with an identical architecture, fuel filter components will soon become an integral part of automotive equipment. The modern design makes it possible to reduce the dependence of the machine on fuel quality and to use almost any type of fuel without burdening the environment.

Cylinder components

The product range includes piston components, bearings, cylindrical liners, connecting rods and piston rings, connecting rods and bushings. Mahle cylinder parts are characterized by the highest precision and high strength through the use of wear-resistant anti-friction alloys and metal processing and hardening methods, including PVD or DLC (Diamond Like Carbon). The production uses the concept of multi-static parts, which allows to increase the strength and wear resistance of the components.

Air conditioners

Already today, HVAC air conditioning systems are distinguished by their unique functionality, they are aimed at complex functions for cooling the engine and passenger compartment, providing a fundamental increase in the level of vehicle safety. The direction includes the production of accessories and components. For example, air supply systems designed to maintain thermal and acoustic comfort, diffusers for aromatizing the car interior, special air filters for purifying the air in the cabin.

HVAC modules are also effective in reducing fuel consumption. The company aims to reduce the overall weight of products for use in hybrid vehicles.

Air management

Includes exhaust gas recirculation and air intake control.

Mahle Gmbh can take a leading position among German aftermarket manufacturers thanks to its knowledge-intensive developments in the field of automotive technology. This is one of the promising representatives of the European automotive market, offering advanced solutions that will become the flagship of automotive technology in the near future.

Among the leading German manufacturers of spare parts are also AE, ATE, AVA, BERU AG, DELLO, FEBEST, MANN, MEYLE, MOOG, VAG (Volkswagen Group), Victor Reinz, WAHLER and others.

European parts manufacturers

Despite the fact that the leading position among European manufacturers of spare parts is occupied by German enterprises, the European automotive industry, located in other countries, shows strong growth rates. Among the leaders are the British GKN, a number of Dutch, Czech, Spanish and Polish manufacturers, whose products are in steady demand.

The British manufacturer GKN is the leader among European manufacturers of spare parts for the production of cardan shafts.

GKN has a truly global production, the manufacturer is represented in 30 countries around the world, its enterprises employ about 40 thousand people. The main specialization is related to the automotive engineering of GKN PLC, as well as the production of high-tech products for the aerospace industry. The company is one of the best manufacturers of cardan shafts. The main feature of these products in a special design, including the universal type of hinges, the use of flange connections, seals, as well as steering knuckles.

Cardar shafts GKN have their own design features:

- large bending angle;

- increased resistance to dynamic loads due to the implemented axial displacement and, as a result, a uniform load on the entire shaft structure;

- various flange connections;

- small rotation diameter.

These features form the ideal basis for implementing various transmission concepts.

Dutch ABS brake systems

The Dutch ABS rightfully belongs to the largest European enterprises in the automotive industry. The brake systems of this brand are installed on almost all cars of European, Asian and American production, including vehicles of various carrying capacities. To date, the product range is 20 thousand items, more than 1200 products are available for brake systems. Products are certified according to ATEST, PIMOT, ECE R90, and also comply with KBA, TUV, ISO.

Spanish brake systems BREMBO for Formula 1

The Spanish brand BREMBO offers best-in-class braking systems. This supplier supplies the conveyors of the largest automotive concerns, supplies products to PORSCHE and FERRARI and other premium car manufacturers in need of exclusive braking systems.

It should be noted that in Formula 1 races, brake pads are subjected to extreme loads, discs heat up to 500 ° C, in such conditions only some brands provide guaranteed performance. Among them are BREMBO. These brake pads were installed on Michael Schumacher's car and are used in BMW motorcycles.

Elite British brake pads FERODO

FERODO is considered by automotive experts to be another premium brand for specially designed brake pads. The company began its history in 1897 with the production of brakes for horse-drawn vehicles. Now FERODO has 103 production sites, products are presented in 34 countries, several thousand patented developments are on account. The main feature of brake systems is the use of specialized anti-friction alloys and synthetic materials, a special design that provides minimal wear to parts.

Polish filters FILTRON

The Polish manufacturer FILTRON is part of the Affnia Group automotive concern. The company was founded in 1982, from the very beginning it specialized in high quality filters, now the products are in demand in 16 European countries, the range is 2300 high quality filters. FILTRON is a regular supplier of products to the conveyors of Mercedes-Benz, Volkswagen, SAAB, Jaguar.

star line

The Czech manufacturer Starline demonstrates the most rapid production growth not only among the enterprises of Eastern Europe. Offering high quality parts combined with affordable prices. Now the products are supplied to a number of countries in Europe, North and South America. All offered products have a prolonged service life. Many services in Eastern Europe successfully work with Starline spare parts, satisfying the requirements of drivers for technical excellence and low price of the product.

Starline's best-known products are superior braking systems. Their key advantage is in the ideal geometry, which largely intersects with the principles of bionic design. The purchased components are not inferior to most expensive brake discs, which contributes to the growth in popularity of the entire product line of this Czech company, which rightfully belongs to the largest European manufacturers of spare parts.

Nipparts B.V., The Netherlands

This company is a leading European supplier to most Asian automotive industries. The company began with the supply of spare parts to the Asia-Pacific region, guaranteeing the originality of origin. Nowadays, it continues to be the largest packer and has already become a manufacturer of a number of parts and accessories.

The proposed list of manufacturers is far from complete; there are a number of enterprises in the EU that supply products of medium quality, which, nevertheless, have satisfactory performance properties. Some major German manufacturers are also not reflected. Taken together, it can be argued that the European region is not only a leading automaker, but also a hub for advanced automotive parts.

This area of production has a strategic impact on the entire industry, and achievements in the scientific and technical field allow us to talk about long-term development prospects.