Hyundai Motor Group has developed the world's first continuous variable valve duration (CVVD) technology to be used in future Hyundai and Kia vehicles. The innovation was showcased at Hyundai Motorstudio Goyang on Wednesday with the Smartstream G1.6 T-GDi, the first engine to feature the technology..

CVVD optimizes engine performance and fuel efficiency and is also environmentally friendly. Valve control technology adjusts valve opening and closing times based on driving conditions, delivering improved performance on the 4% and improved fuel efficiency on the 5%. In addition, the technology reduces emissions by 12%..

"The development of CVVD technology is a good example of how Hyundai Motor Group is strengthening our powertrain technology," said Albert Biermann, President and Head of Research and Development at Hyundai Motor Group. "We will continue our innovative efforts to change the paradigm and ensure the sustainability of our business model."

Innovation: continuously variable valve duration

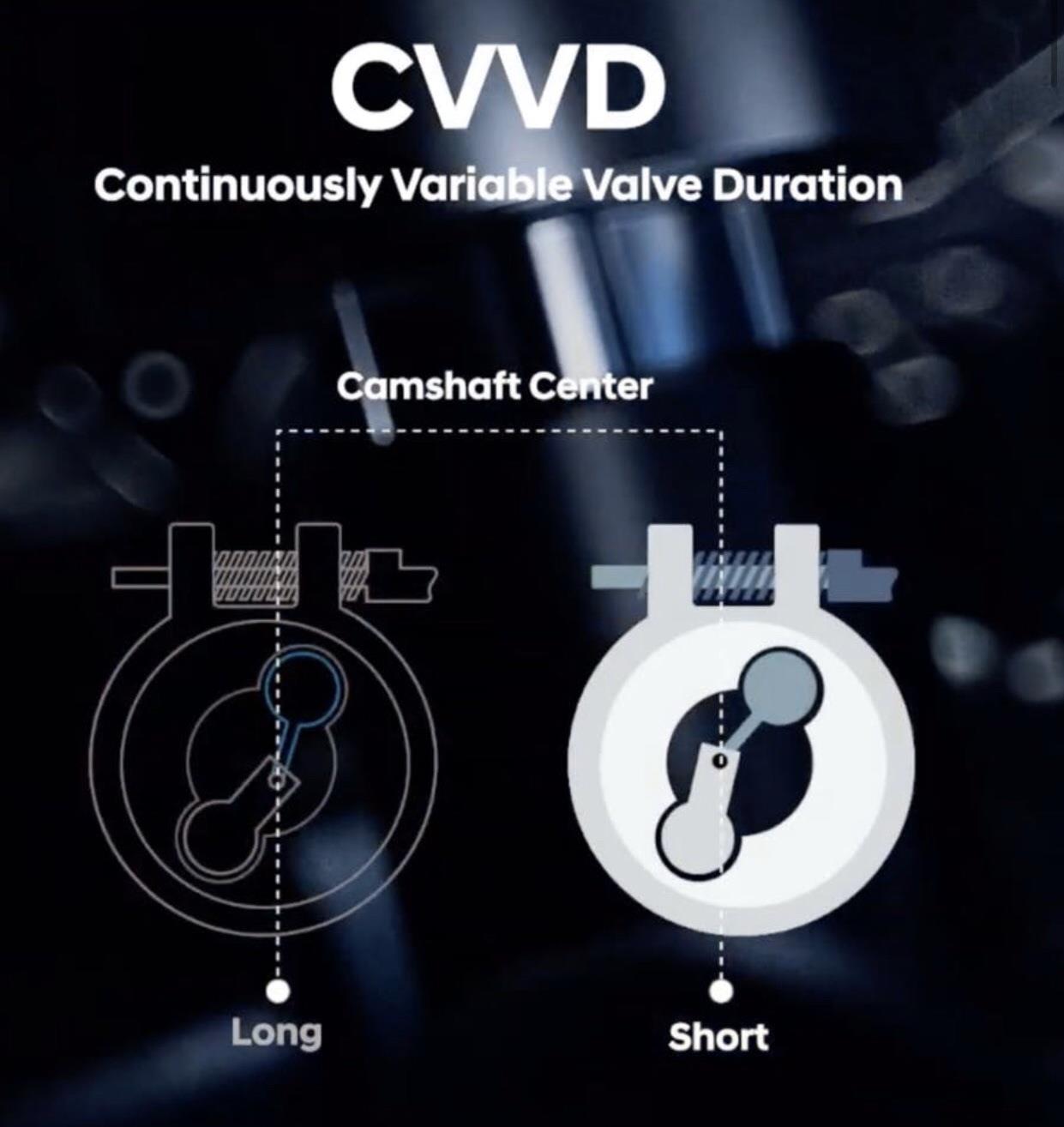

Until now, the performance and efficiency of an internal combustion engine has been controlled by variable valve control technology, which regulates valve opening and closing times and valve opening depth, with engine power produced in an intake-compression-expansion-fuel exhaust cycle.

Typical variable valve control technologies control the timing of valve opening and closing (as in Continuously Variable Valve Timing - CVVT) or control the amount of air entering by adjusting the opening depth (Continuously Variable Valve Lift - CVVL). Previous variable valve control technologies could not control valve duration because valve closing time was subject to open time and could not respond to different driving situations. CVVD takes technology in a new direction by adjusting how long the valve is open.

When the vehicle maintains a constant speed and requires low engine power, CVVD opens the intake valve from the middle to the end of the compression stroke. This helps improve fuel efficiency by reducing drag caused by compression. On the other hand, when engine power is high, such as when a car is moving at high speed, the intake valve closes at the start of the compression stroke to maximize the amount of air used for the explosion, increasing torque to improve acceleration.

Smartstream G1.6 T-GDi Engine

Alongside the new CVVD technology, the new Smartstream G1.6 T-GDi engine, a four-cylinder petrol turbo unit with 180 horsepower and 27.0 kg of torque, was introduced. The new powertrain is the first to use the Group's new CVVD technology and also features Low Pressure Exhaust Gas Recirculation (LP EGR) to further optimize fuel efficiency.

The exhaust gas recirculation system returns part of the gas burned by the engine to the combustion chamber, producing a cooling effect and reducing nitrogen oxide emissions. The G1.6 T-GDi also features a low pressure system that redirects burnt exhaust gas to the front of the turbocharger's compressor rather than the intake system to improve efficiency under high load conditions.

In addition, the new unit has an integrated thermal management system that quickly heats or cools the engine to the optimum temperature, as well as a powerful direct spray system that reaches 350 bar, surpassing the 250 bar of the previous T-GDi engine. In addition, engine friction is reduced on the 34% by using low friction moving parts.

The new Smartstream G1.6 T-GDi engine will be used in the Hyundai Sonata Turbo, which is scheduled for release in the second half of this year. This premiere will be the first in a series of new vehicles powered by Hyundai and Kia. Information about Kia's first powered vehicle will be revealed at a later date, around the vehicle's launch date. Watch a video about the new engine technology at the following link: https://youtu.be/5atYksEpAm8